BT5060 – BT5060A2

Unit Dose Fully Automatic

Medicine Cutting and Packaging Systems

It is a device that automatically cuts and packs ampoules, vials and blister-packaged (tablet/capsule/dragee) medicines to be prepared for use by patients in the pharmacy units of health institutions.

There is a labeling program on the main control computer and there is a database in it. All drug information can be saved, changed or deleted in this database. At the same time, it is possible to get a large number of prints instantly by making manual entry for drugs that are not in the database.

Blister Cutting & Packaging (BT5060)

Blister packaged products (tablets / capsules / dragees) are made into unit doses by cutting the blister in appropriate sizes without deblistering. These drugs, which are made into unit doses, are allowed to fall into the bag one by one. The desired drug information is written on the bag and instant drug tracking is provided with unit dose packaging.

Ampoule/Vial packaging (BT5060A2)

An ampoule or vial is placed in the feeding chamber of the device. The placed drug is selected from the system. Medication information is checked, necessary corrections are made, and a work order is created by determining the amount of medication to be printed.

SYSTEM FEATURES

The system is automatically bagged by placing the drugs to be packaged in the chamber integrated into the system.

The air-open bag is supported and provides fast packaging.

It has automatic blister recognition facility.

It has the most advanced cutting system in the market by providing a special cut according to the types of blisters with only 2 mm distance between the drugs in the blister.

It has a high unit dose production capacity and provides blister cutting, packaging, printing and automatic closing processes.

It is a compact device and an area of 1m² is sufficient.

Packing of all ampoules is ensured with the automatic ampoule feeding feature. (3 different discs are used.)

Label design and page structure can be adjusted and updated.

It can be adjusted according to the bag length via the label program.

Printer control menu and system setting menu are available on the machine.

During the packaging process, it is possible to track how many packages were made and how many bags were packaged on the screen.

It is possible to access the system with a user name and password. It complies with safety rules and CE standard.

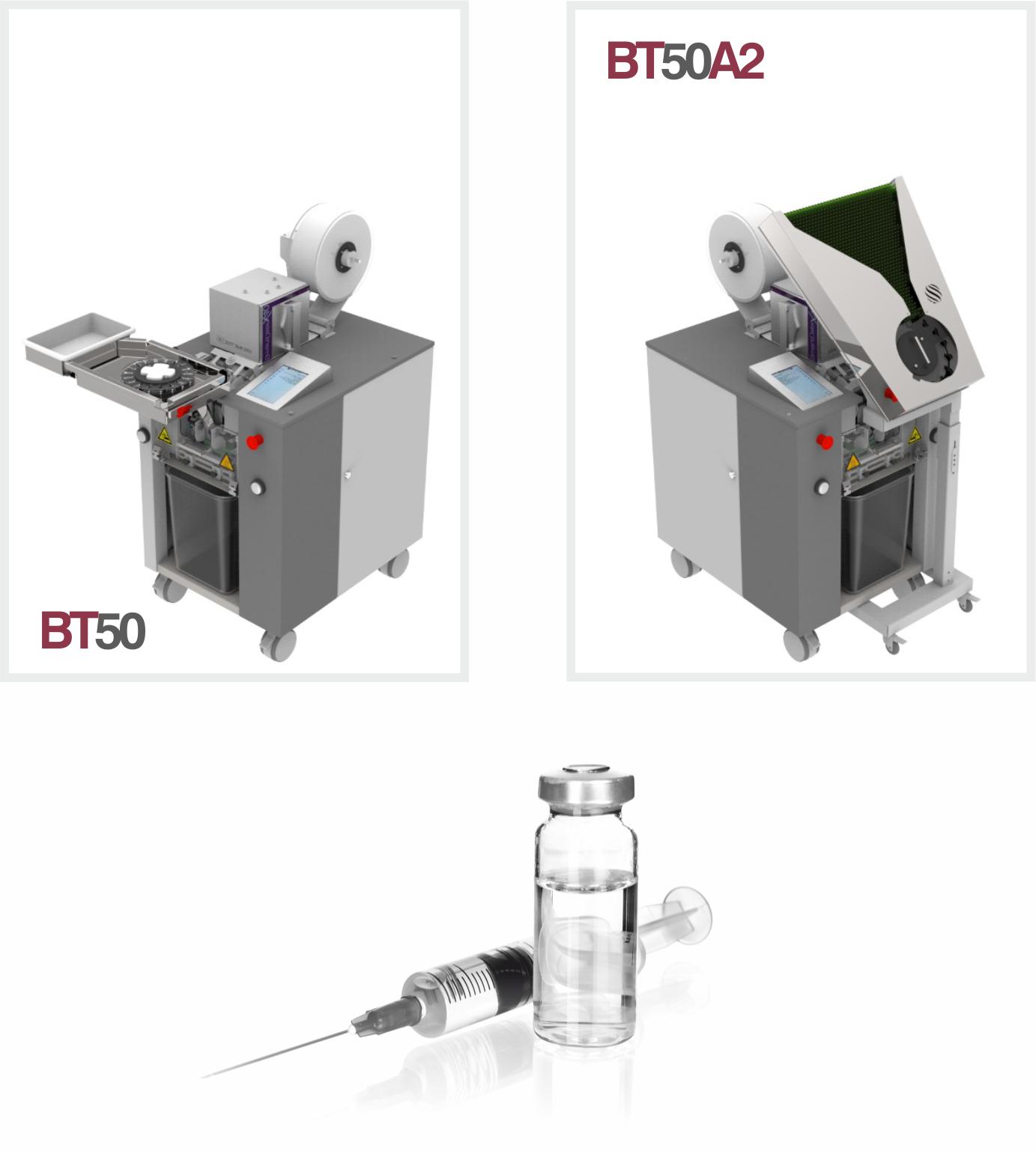

BT50 – BT50A2

Semi Automatic

Medicine Packaging Systems

It can work in automatic or semi-automatic mode, ampoule, vial and blister package (tablet / capsule / dragee) bottle etc. It is the device that packs the products.

Ampoule/Vial packaging (BT50A2)

Packing of all ampoules is ensured with the automatic ampoule feeding feature. (3 different discs are used.)

Ampoule/Vial and Blister packaging (BT50)

In semi-automatic mode, the packaging of ampoules, vials and blister-packaged (tablet/capsule/dragee) type drugs is provided. (5 different discs are used.)

Printer control menu and system setting menu are available on the touch screen

High productivity

Easy to use

Access to the system with user name and password

It complies with safety rules and CE standard

BT60

Automatic

Blister Cutting Machine

Fully computerized and automated solution for blister cutting

Ease of use with 7 inch touch screen panel

High standard PVC and PET/Aluminum blister sheet cutting capabilities

Small footprint sizes

High productivity

Easy to use

Adaptable and scalable

It complies with safety rules and CE standard

Auxiliary Units

Bag Features